CuP8 Brazing Filler Metal

CuP8 is a copper-phosphorous brazing alloy, with excellent flow properties. It can be used to join copper to copper or copper based base materials. Copper-phosphorus brazing filler has been widely used in brazing copper and copper alloys due to its good process performance and low price. The addition of phosphorus can reduce the melting point of the solder and play a role in self-brazing when brazing copper in the air.

Note: Powder/Paste are affordable.

Copper Based Brazing Alloy:

AWS |

Chemical Composition(wt%) |

Solid Liquid Phase(℃) |

Brazing Temperature(℃) |

BCu100/BCu-1 |

Cu≥99.9 |

1083 |

1093-1149 |

CuSn10 |

Sn9-11/Cu Bal |

840-1000 |

1020-1090 |

CuSn19Ti10 |

Sn18-20/Ti9-11/Cu Bal |

850-880 |

880-930 |

BCuP-2/BCu92P |

P7-9/Cu Bal. |

710-770 |

720-843 |

CuSn3P7 |

P6-8/Sn2-4/Cu Bal. |

630-670 |

710-810 |

BCuP-9/BCu86SnP |

P6-7/Sn6-7/Cu Bal. |

650-700 |

700-810 |

BCuP-8/BCu76AgP |

Ag17.2-18/P6-6.7/Cu Bal |

643-666 |

670-686 |

BCu86SnPNi |

P4.8-6.5/Sn7-8/Ni0.5-1.5/Cu Bal |

612-682 |

682-812 |

CuSn15.6PNi4.2 |

P4.8-6.5/Sn7-8/Ni0.5-1.5/Cu Bal |

585-605 |

605-800 |

Cu595/BCu84NiMn |

Mn11-13/Ni2-4/Cu Bal |

970-990 |

1000-1050 |

CuMn38Ni10 |

Mn37-39/Ni9-11/Cu Bal |

900-950 |

950-1070 |

BCuMnCo |

Mn9-11/Co2-4/Cu Bal |

980-1030 |

1050-1100 |

BCu54Zn |

Cu53-55/Zn Bal |

885-888 |

910-955 |

Cu55ZnMnNi |

Cu54-56/Ni6-8/Mn4-6/Zn Bal |

910-933 |

940-1040 |

Product Properties

1. Form:Powder/Paste

2. Solid Liquid Phase:643-666℃

3. Brazing Temperature: 670-686℃

4. Suitable Base Material:Copper/Copper Alloy

Application

It is widely used in Copper/Copper Alloy brazing

Hot Tags: cup8 brazing filler metal, China, suppliers, factory, customized, price, cheap, for coating, for 3D printing, Niobium Powder, 18Ni300 Powder, BNi-7 Brazing Filler Metal, High Purity Low Oxygen HDH Sponge Titanium Powder, Flake Silver Powder, BNi-5 Brazing Filler Metal

|

CuSn10 Brazing Filler Metal

It is often used for brazing steel and stainless steel in furnaces. Compared with pure copper brazing filler metals, the brazing temperature is slightly lower, which helps to prolong the service life of brazing furnaces and reduce the damage of base metal.

Note: Powder/Paste are affordable.

Copper Based Brazing Alloy:

AWS |

Chemical Composition(wt%) |

Solid Liquid Phase(℃) |

Brazing Temperature(℃) |

BCu100/BCu-1 |

Cu≥99.9 |

1083 |

1093-1149 |

CuSn10 |

Sn9-11/Cu Bal |

840-1000 |

1020-1090 |

CuSn19Ti10 |

Sn18-20/Ti9-11/Cu Bal |

850-880 |

880-930 |

BCuP-2/BCu92P |

P7-9/Cu Bal. |

710-770 |

720-843 |

CuSn3P7 |

P6-8/Sn2-4/Cu Bal. |

630-670 |

710-810 |

BCuP-9/BCu86SnP |

P6-7/Sn6-7/Cu Bal. |

650-700 |

700-810 |

BCuP-8/BCu76AgP |

Ag17.2-18/P6-6.7/Cu Bal |

643-666 |

670-686 |

BCu86SnPNi |

P4.8-6.5/Sn7-8/Ni0.5-1.5/Cu Bal |

612-682 |

682-812 |

CuSn15.6PNi4.2 |

P4.8-6.5/Sn7-8/Ni0.5-1.5/Cu Bal |

585-605 |

605-800 |

Cu595/BCu84NiMn |

Mn11-13/Ni2-4/Cu Bal |

970-990 |

1000-1050 |

CuMn38Ni10 |

Mn37-39/Ni9-11/Cu Bal |

900-950 |

950-1070 |

BCuMnCo |

Mn9-11/Co2-4/Cu Bal |

980-1030 |

1050-1100 |

BCu54Zn |

Cu53-55/Zn Bal |

885-888 |

910-955 |

Cu55ZnMnNi |

Cu54-56/Ni6-8/Mn4-6/Zn Bal |

910-933 |

940-1040 |

Product Properties

1. Form:Powder/Paste

2. Solid Liquid Phase:1083℃

3. Brazing Temperature: 1093-1149℃

4. Suitable Base Material:Copper Alloy/Steel/Tantalum Niobium Supperalloy

Application

It is widely used in brazing, Powder Metallurgy Products, Catalysts, Thermally Conductive and Electrically Conductive Materials

Hot Tags: cusn10 brazing filler metal, China, suppliers, factory, customized, price, cheap, for coating, for 3D printing, CoCrW Powder, Rare Earth Products, AgCuTi Brazing Filler Metal, Molybdenum Powder, BNi-5 Brazing Filler Metal, CuSnTi Brazing Filler Metal

|

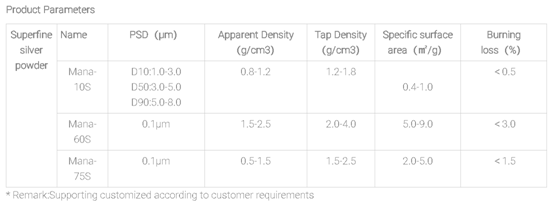

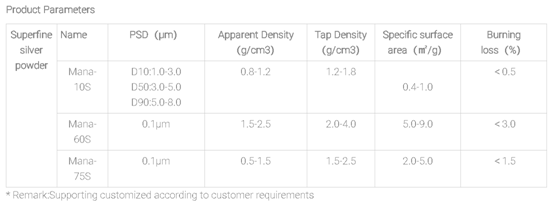

Superfine Silver Powder

Superfine silver powder is is an important material in electrical and electronic industry.It is a kind of precious metal powder widely used in electronic industry.

Electronic components production process, to use the silver powder slurry, which should have a special high purity (silver content greater than 99.99%), super fine (average particle size 0.2-0.4μm), our company can stable production and provide this kind of silver powder.

Raw materials and processes that have important influence on the purity and morphology of silver powder: 1, reducing agent and reduction reaction rate; 2, additives; 3, reduction reaction temperature; 4, cleaning of silver powder.

Equipment affecting the size, size distribution and morphology of silver powder:Reduction kettle,dryer.

Application:

1. Antibacterial virus: approximately 0.1% of the nano silver on Escherichia coli, Staphylococcus staphylococcus and other dozens of pathogenic micro-organisms has a strong inhibitory and killing effect.

2. Anti-bacterial, anti-corrosion coatings can also be applied in the protection of cultural relics.

3. Used for preparation of the production of microelectronic components wiring, packaging, connectors.

4. Silver powder is used to produce electronic slurry of microelectronic devices and circuit miniaturization.

5. Efficient catalysts: Silver powder used as catalyst, high efficiency, selectivity, and can be used in the reaction process of methanol synthesis catalyst CO2 and H and the like.

6.Widely used in preparing thick film conductor paste。

High Purity Tellurium Metal Ingot

Purity |

99.99%, 99.999%, 99.99999% |

Density (Tap) |

6.24 g/cm3 |

Melting Point |

449.5 °C, 722 K, 841 °F |

Boiling Point |

998 °C (1,828 °F; 1,271 K) |

Electronegativity |

2.01 |

Bandwidth |

0.35eV |

Specific Heat |

0.0481 Cal/g/K @ 25°C |

Thermal Conductivity |

2.35 W/m/K |

Description:

Tellurium is a non-metallic element recovered as a by-product of electrolytic copper refining. Santech produces Tellurium in various shapes and sizes, such as ingot, powder and grains and a wide range of purity from 99.5% to 99.999%. Tellurium is a semiconductor that shows a greater electrical conductivity in certain directions which depends on atomic alignment, the conductivity increases slightly when exposed to light (photoconductivity). Tellurium is mainly used in the field of CdTe solar cell, Bi2Te3 thermo-electric compounds, metallurgy, vulcanization of rubber.

Specifications:

Element |

Standard % |

Element |

Standard % |

Cu |

<0.001 |

Si |

<0.001 |

Mg |

<0.001 |

Al |

<0.001 |

Bi |

<0.001 |

Se |

<0.002 |

Fe |

<0.001 |

Pb |

<0.002 |

As |

<0.0005 |

Na |

<0.003 |

S |

<0.001 |

|

|

Purity |

99.99%, 99.999% |

Density |

5.67 g/cm3 |

Melting Point |

733 °C |

Boiling Point |

1,260 °C |

Transparency Range |

0.35 - 5.0 nm |

Thermal Conductivity |

30 mW/cm °C |

Particle Size |

D50=10-12μm |

Description

Tellurium oxide is obtained by adding sulphuric acid to an alkaline solution of tellurium,it remains stable in air and burns with a green flame giving off bioxide. It is an amphoteric substance and therefore can act both as an acid or as a base depending on the solution it is in. It reacts with acids to make tellurium salts and bases to make tellurites. It can be oxidized to telluric acid or tellurates. Tellurium dioxide is used as a catalyst for rubber and for metal surface treatment, corrosion resistance, identification of bacteria in vaccines.

Specifications:

Grade |

ICP(OES)Inductively Coupled Plasma Optical Emission Spectroscopy

Concentration - (ppm by wt) |

Element |

Standard |

Element |

Standard |

Cu |

2.0 |

Ca |

10.0 |

Ag |

2.0 |

Fe |

5.0 |

Mg |

5.0 |

As |

10.0 |

Sb |

5.0 |

Al |

5.0 |

Zn |

10.0 |

Pb |

10.0 |

Bi |

10.0 |

Sn |

2.0 |

Purity |

99.9%, 99.99% |

Crystal Structure |

α type, β type |

Particle Size (D50) |

range of 1-5um, 5-10um, 10-20um |

Density (Tap) |

2.0 ~ 3.5 g/cm3 |

Melting point |

817 °C, 1090 K, 1503 °F |

Boiling point |

1,890 °C (3,430 °F; 2,160 K) |

BET Surface Area |

0.9831 m2/g |

Thermal expension coefficient |

5.89 (10-6/°C) at 101°C |

Description

Bismuth Trioxide is the important compound of Bismuth, beta-Bismuth Trioxide is orange color, and alpha Bismuth Oxide is the light yellow color which is widely used in the market which can be used as electronic materials, thermistor, glass coloring, varistor, surge arresters, CRT, fireproof paper, nuclear reactor fuel, electronic etc. Santech Materials has more than 10 years experience in production of the high purity Bismuth Trioxide, and provides full support for your business with the technical support, proffesional sales team and good after-sell service.

Specifications:

Element |

Standard % |

Element |

Standard % |

Li |

≤0.0005 |

Na |

≤0.005 |

K |

≤0.003 |

Ca |

≤0.003 |

Mg |

≤0.0007 |

Al |

≤0.002 |

Si |

≤0.005 |

As |

≤0.002 |

Cd |

≤0.0005 |

Fe |

≤0.001 |

Sn |

≤0.0005 |

Cr |

≤0.0008 |

Ni |

≤0.0005 |

Cu |

≤0.0008 |

Pb |

≤0.0008 |

Ag |

≤0.001 |

Sb |

≤0.0008 |

Cl |

≤0.001 |

Sulfate Radical SO4 |

≤0.001 |

Loss on Ignition |

≤0.3 |

Unsolvable in HNO3 |

≤0.01 |

D50 |

1 ~ 5 micron |

|